Fleet maintenance has traditionally been built around schedules, inspections, and experience. Preventive maintenance intervals, driver reports, and periodic shop checks form the backbone of most maintenance programs. While these practices are absolutely essential, they leave a significant gap between inspections where emerging issues can go unnoticed until they become costly failures.

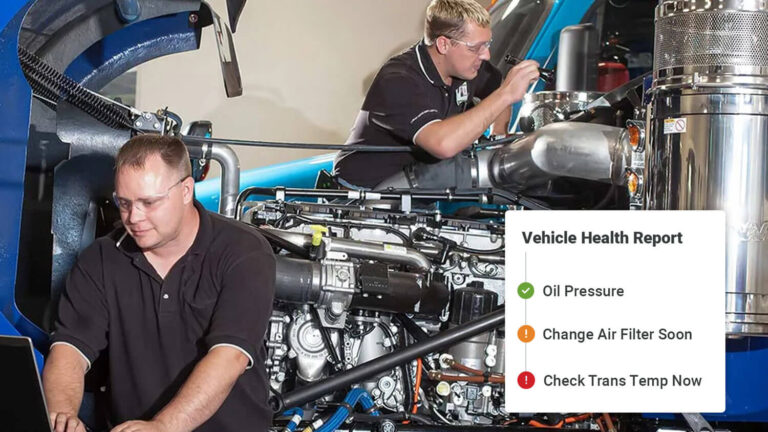

3rd Eye Fleet Maintenance and Chassis Health software solutions address this gap by shifting maintenance from a reactive or calendar-based approach to one that is driven by real operational data. By continuously monitoring vehicle, body, and equipment health as assets operate in the field, fleets gain the visibility needed to identify issues early, plan repairs intelligently, and protect uptime without adding burden to drivers or technicians.

Why traditional maintenance strategies fall short

Even the very best maintenance teams are hampered by limited visibility. Inspections only capture a moment in time. Preventive maintenance intervals are based on averages rather than actual conditions. Driver reports are subjective and often delayed. Between these touchpoints, vehicles continue to operate under varying loads, environments, and duty cycles that directly affect component health.

As a result, many failures are not surprises in hindsight. Without continuous monitoring, these signals remain invisible until a breakdown forces emergency attention. Downtime increases, spare utilization rises, and work orders become reactive rather than planned, often disrupting an entire shop schedule and pulling technicians away from other critical work.

The issue is not a lack of skill or effort. It is a lack of real-time insight into what is happening between inspections.

What chassis health monitoring changes

Chassis health solutions are designed to close this visibility gap. Instead of relying solely on scheduled checks, systems continuously monitor thousands of data points across the chassis, body, and connected equipment while vehicles operate under normal conditions.

This approach allows fleets to detect subtle changes in performance that indicate developing issues. Alerts are generated before failures occur, giving maintenance teams time to respond on their own terms rather than under pressure.

More importantly, alerts are prioritized based on severity and time until failure. Maintenance teams are not overwhelmed with noise. They receive clear, actionable insight into what needs attention first and why.

From reactive repairs to condition-based maintenance

Condition-based maintenance replaces assumptions or “gut feelings” with evidence. Rather than servicing components because a mileage threshold has been reached, teams can focus on assets that are showing real signs of wear or degradation.

This improves maintenance efficiency in several ways:

- Repairs are planned instead of rushed

- Parts are replaced when needed, not prematurely

- Labor is allocated based on urgency and impact

- Vehicles spend more time in service and less time in the shop

- Over time, this discipline reduces downtime, stabilizes maintenance costs, and improves overall fleet reliability.

- Improving work order execution and technician effectiveness

One of the less visible challenges in fleet maintenance is diagnostic time. Identifying the root cause of an issue often consumes more labor than the repair itself, especially when less experienced technicians are involved.

3rd Eye Fleet Maintenance and Chassis Health technology helps address this by providing detailed context with each alert. Maintenance teams receive information on what is occurring, where it is occurring, and how it is trending over time. In many cases, technicians are also provided with clear repair guidance, reducing guesswork and minimizing diagnostic errors.

This not only improves uptime but also helps standardize maintenance quality across shifts, locations, and technician experience levels.

Reducing reliance on spares and emergency repairs

Emergency breakdowns often drive fleets to maintain larger spare inventories as necessary insurance against downtime. While spares provide flexibility, they also tie up capital and increase storage and maintenance requirements.

By predicting issues before failure, chassis health monitoring allows fleets to reduce their reliance on spares. Vehicles can be scheduled for service proactively, minimizing the need for last-minute substitutions and route disruptions.

The result is a more stable operation where maintenance decisions support production goals rather than disrupt them.

Integrating chassis and body health for refuse fleets

For refuse, utility, and other vocational fleets, chassis health alone does not tell the full story. Body functions such as compaction, lifting, and stationary operation place significant demands on hydraulic and mechanical systems that are not captured by mileage-based maintenance programs.

Integrated chassis and body health monitoring provides a more complete view of vehicle condition. By processing data directly from body control systems, fleets gain insight into how equipment is performing during real-world operation. This allows maintenance teams to address body-related issues with the same discipline and foresight applied to the chassis.

The result is fewer body-related breakdowns, improved route reliability, and more consistent service delivery.

Data that supports smarter decisions beyond maintenance

Chassis health data delivers value well beyond the shop. When fleets understand how vehicles perform across routes, environments, and duty cycles, leadership gains insight into broader operational trends.

This information can inform decisions related to equipment selection, route planning, utilization strategies, and long-term capital planning. Finance teams benefit from improved cost predictability, while operations teams gain confidence that assets are being maintained based on actual need rather than assumptions.

Building a more disciplined maintenance culture

The most effective maintenance programs are not defined by tools alone. They are defined by discipline and consistency. Fleet Maintenance and Chassis Health solutions support this by providing objective data that aligns teams around the same source of truth.

Instead of debating whether an issue exists, teams can focus on when and how to address it. Maintenance becomes a proactive function that supports operations, safety, and customer service rather than reacting to failures after they occur.

Why fleets adopt 3rd Eye chassis health solutions

3rd Eye approaches fleet maintenance from an operational perspective. Chassis, body, and equipment health are monitored continuously and passively, without adding work for drivers or technicians. Alerts are prioritized, actionable, and are tied to real vehicle activity.

By integrating health monitoring with broader Connected Collections integrated fleet solutions, 3rd Eye helps organizations move from reactive maintenance to a data-driven, condition-based approach that protects uptime and simplifies decision making.

Bringing predictability back to fleet maintenance

Fleet maintenance will always depend on skilled technicians, smart processes, and disciplined execution. What has changed is the ability to see what is happening between inspections and service intervals, where many costly failures begin.

3rd Eye Fleet Maintenance and Chassis Health solutions give fleets earlier visibility into emerging issues, allowing maintenance teams to plan repairs intelligently, protect uptime, and reduce unnecessary disruption. For organizations focused on reliability, cost control, and long-term asset performance, this level of operational insight has become a core requirement for successful modern fleet management.

Learn more about 3rd Eye Fleet & Chassis Health Software Technology